| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

AKDI MAKİNE SAN. VE TİC. LTD. ŞTİ.

Büyükkayacık OSB Mah. 101. Cad D1 Blok No: 6B / Selçuklu / KONYA / TÜRKİYE

|

Contact Info: +90 553 015 2205

|

Hall: 4

Stand: 401/C

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

In our projects, we have solutions for the production of special machines and automation. We develop solution-oriented systems for both needs in process development and new processes. With the projects we develop in the automotive industry, manufacturing industry, durable consumer industry and metal manufacturing sectors, we increase the competitiveness of our customers by reducing the operating costs by making high-quality, operator-independent rapid production.

Our furnace, which ensures that the molds used in production are heated before the operation starts and reach the ready temperature for production, reaches a maximum temperature of 250°C. It has a temperature control sensitivity of 1°C. Its construction is made of structural steel and its sheets are painted with static paint.

Our furnace, which heats the products, reaches a maximum temperature of 200°C, and has a temperature control accuracy of 1°C in routine operation at the set temperature of 200°C. To the furnace chambers, the ingredients are placed on trays with 4 trolleys each, and they are driven into the furnace via a ramp system. The system eliminates the problem of burning hands when the trolley leaves the furnace with the door lock feature that opens when the furnace cools down.

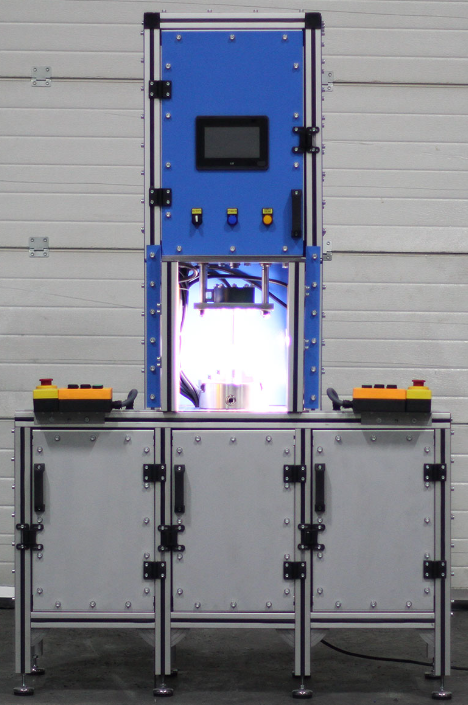

It is used to measure whether there is any deformation or adhesion in elastomer automotive suspension system bushings and to measure the deflection values at standard loads. This test device is designed to test products under mass production conditions. The device allows the parts to advance with 0.025 mm precision and their force to be measured with 1 kg precision, ensuring 100% control and verification of production according to material properties and visual suitability.

It is used to measure whether there is any deformation or adhesion in elastomer automotive suspension system bushings and the flexibility values at standard loads. The outer body of the bushing is placed in the adjustable lathe chuck. A spindle is used to apply pressure to the center of the bushing. The pressure load is verified by an external pressure transmitter. In the device, which operates with a pneumatic system, the load to be applied to the bushing can be adjusted via the touch panel.

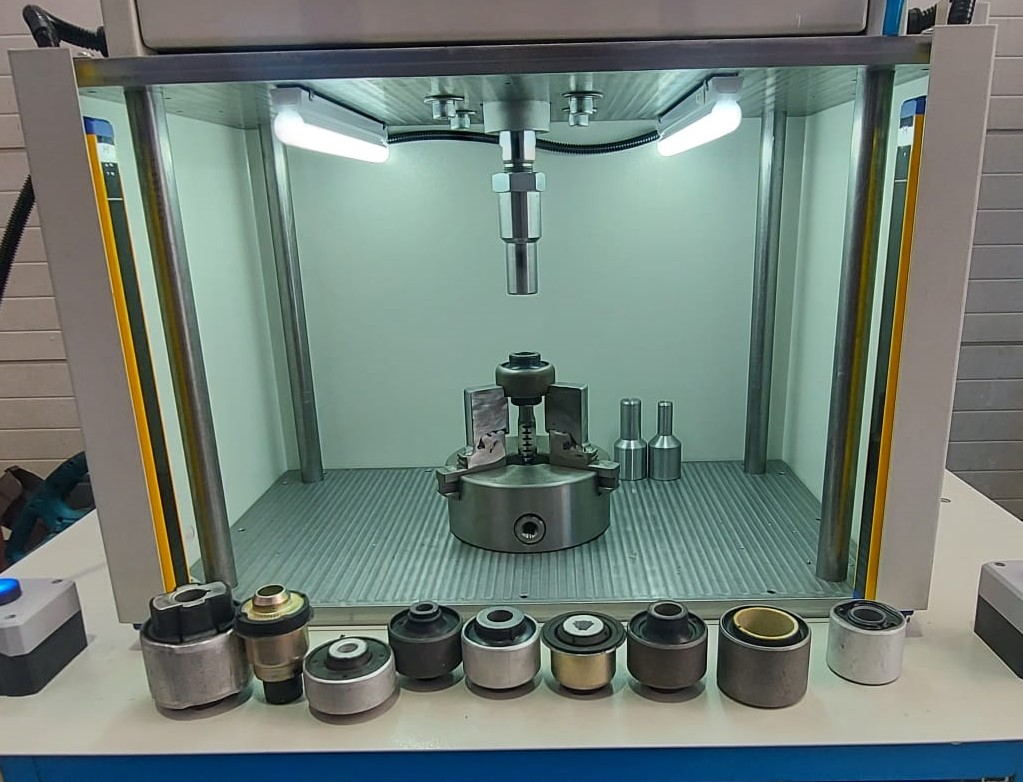

The compliance of many products such as steel materials, cast iron materials, aluminum alloy materials, concrete materials, plastic materials with standards can be tested with the Universal Tensile Compression Testing Machine. Our devices are produced with 3 different methods: servo motor driven, AC motor driven and hydraulic power driven. The choice of method is determined according to the usage area of the device, the tests it will perform and the maximum load capacity. The capacity of our double column screw shaft structure test devices is up to 300 KN. Servo motor driven electromechanical devices are recommended in places where waiting under load is required, such as bolt tests, or for functional tests. AC motor driven ball screw systems are recommended for systems where only pulling will be done at low loads.

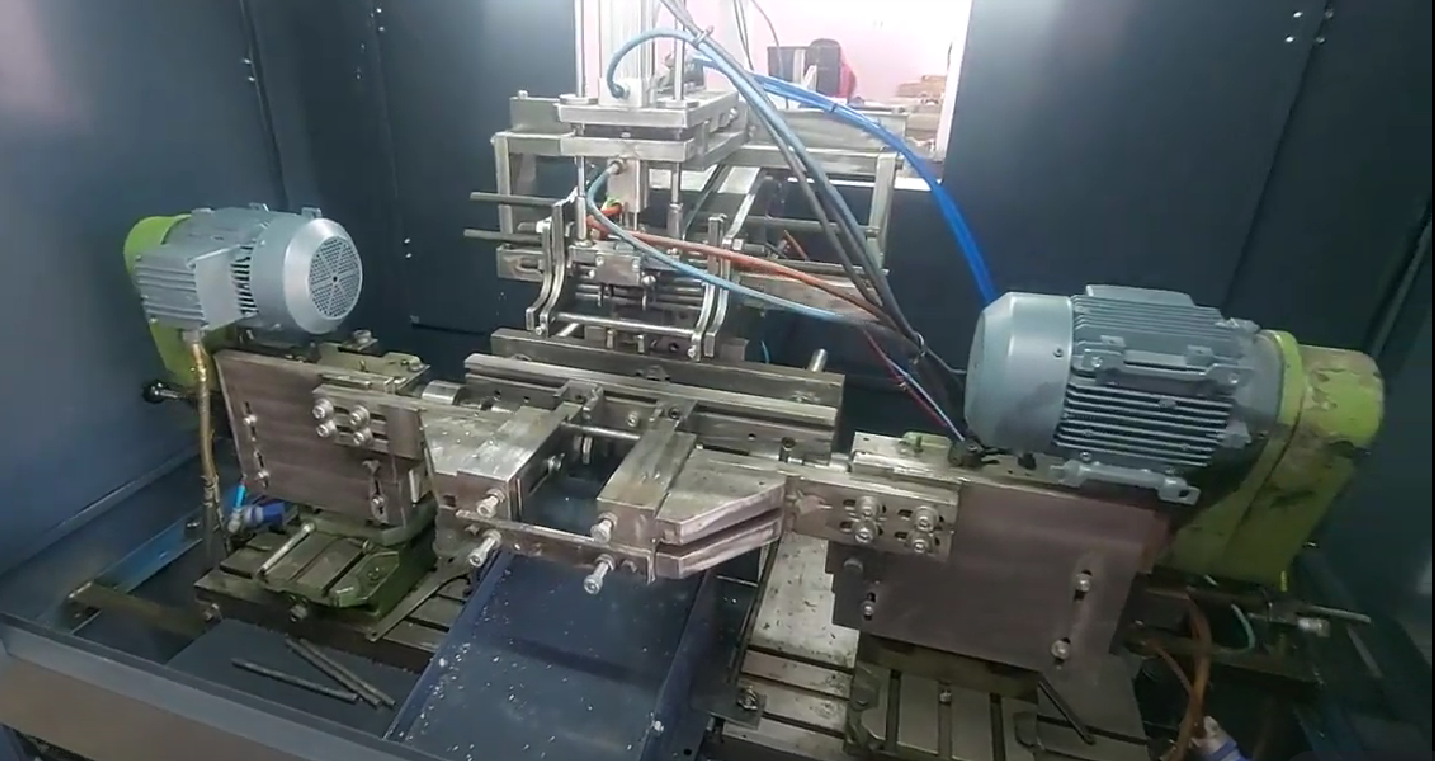

The device is used to deburr and chamfer edges of materials such as metal or wood. The workpiece diameter measures 6-14 mm and the sample length varies between 60-300 mm. The products are placed in the feeding section manually by the operator. The incoming material is taken with the jaws and positioned for chamfering. The bits coming with the motors moving from both sides perform the chamfering process on the part, then the part passes from the ramp to the pan and the process is completed.

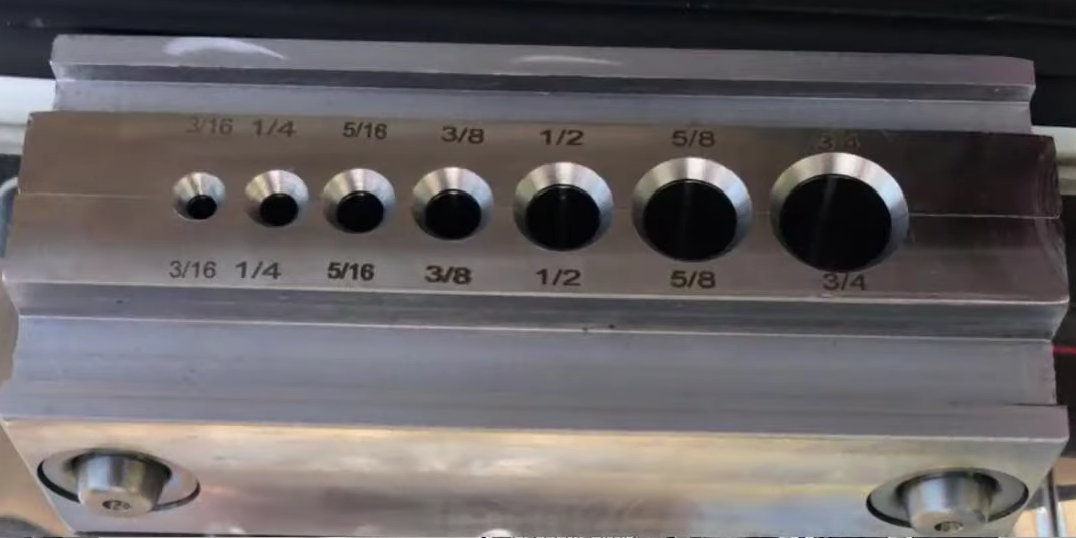

The device countersinks all metallic materials such as steel, aluminum and copper. The process is carried out to a standard extent with a support on the machine. There are places in the jaw according to diameters to process materials of different diameters. The process is carried out by placing the material in a place suitable for the diameter of the material with the help of pins.

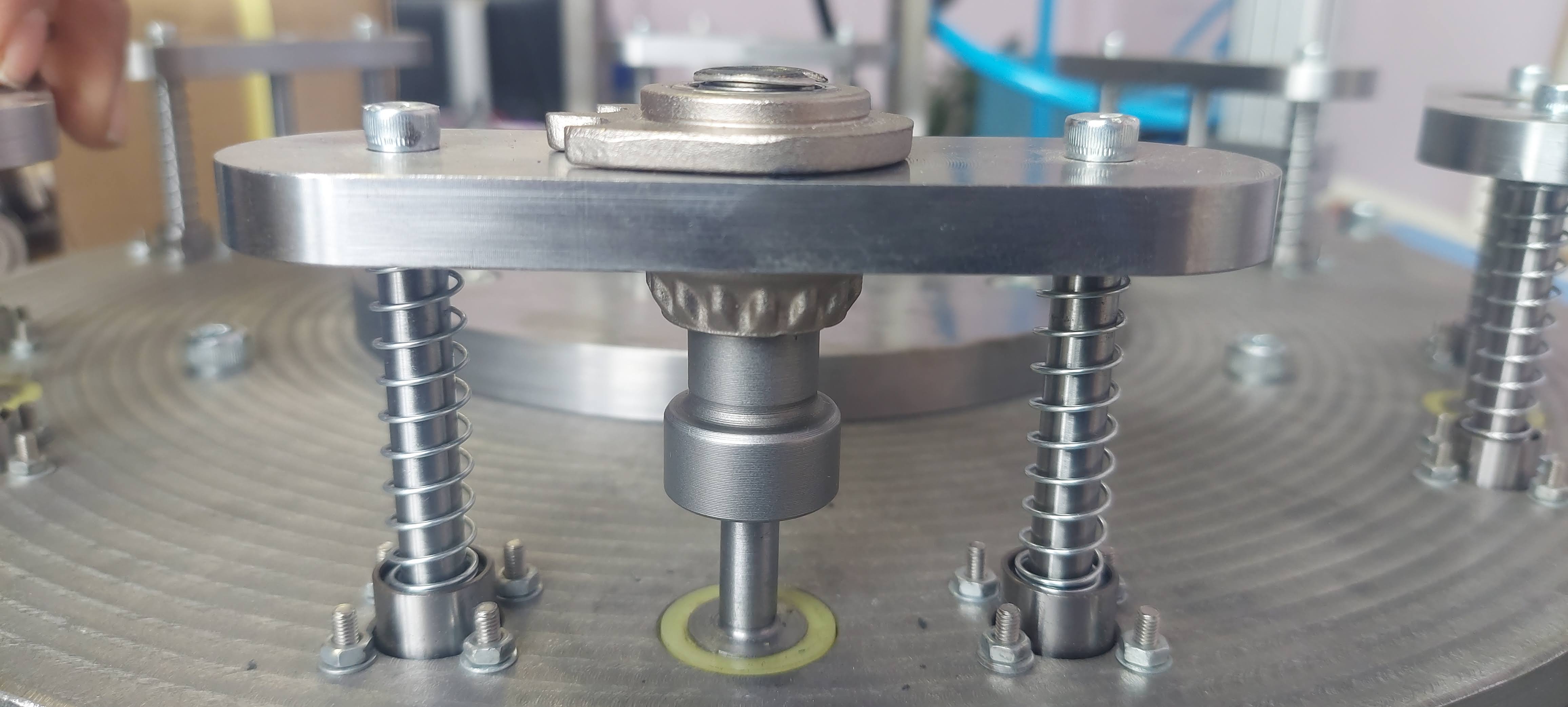

The device has a rotating drum and assembles 4 different components together using pneumatics at 4 different stations. Pneumatics are load and speed controlled and assembly control is verified by sensors. Feeding is done by the operator and the assembled product is exited from the system by a robot gripper.

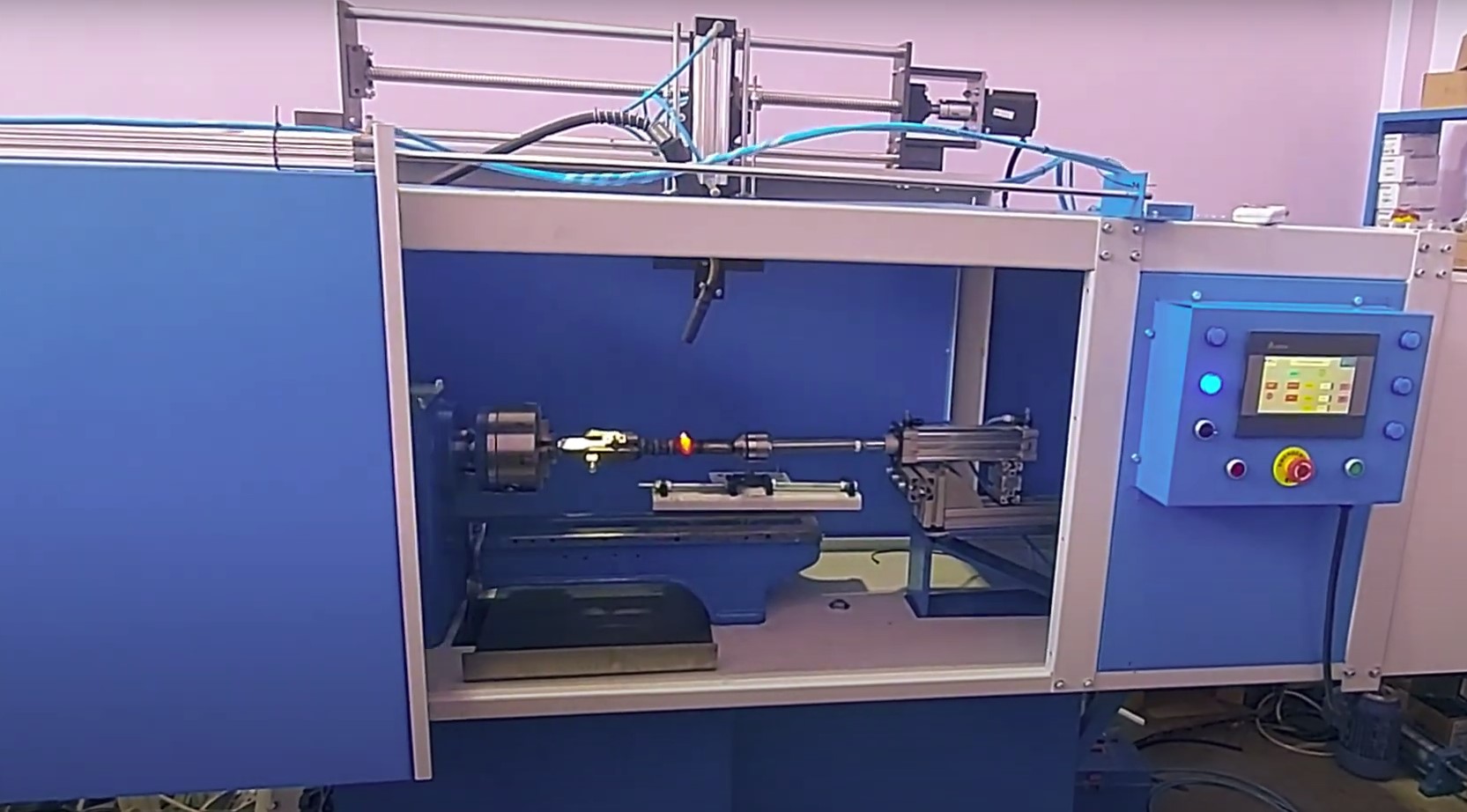

With the rotary environmental welding machine, gas arc welding can be easily done in an environmentally friendly manner. Welding fixtures specific to any part can be designed. Tailstock movement distance is 1 m. The welding torch is adjusted pneumatically in 2 axes.

It is a 3-axis servo, double-acting press used in the powder metallurgy production process. It is used to shape powders in molds before sintering. It works fully automatically with powder feeding.

No represented companies found.

- AKDI MÜHENDİSLİK

TR

TR