| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

AKYAPAK MAKİNA SANAYİ TİCARET A. Ş.

HASANAĞA OSB MAH. HOSAB SANAYİ CAD. NO: 62 / NİLÜFER / BURSA / TÜRKİYE

|

Contact Info: +90 224 280 7500

|

Hall: 4

Stand: 402/403

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

HIGH TECHNOLOGY FROM TURKEY TO THE WORLD AKYAPAK, which is a long established company from Bursa, exporting metal-bending, cutting, and drilling machines to 120 countries in 6 continents is celebrating its 60thyear anniversary AKYAPAK having a success story for more than a half century has successfully brought the high quality symbolizing Turkish power to the world. To reinforce its strong image throughout the world, Akyapak has taken new steps and has lastly formed Akyapak USA and Akyapak Russia offices opened in Tampa and Moscow. AKYAPAK with technological manufacturing facilities of 32 thousand square meters is a source of pride for both Bursa and Turkey AKYAPAK established in 1962 in Bursa has reached its worldwide fame with pertinacity from the first day on and following the innovation and technology closely. AKYAPAK, having its manufacturing plant and headquarters in Bursa, continues to develop technology in Turkey with its regularly trained 320 experienced staff. AKYAPAK presents its products to the wrold with different brand names as AKBEND for Plate, Pipe, and Profile Bending Machines, AKDRILL for Drilling Lines, AKWELD for Welding Solutions. For Oxy-Plasma Cutting, Flanging and Dish-End machines, it uses AKYAPAK main brand name. AKYAPAK machines provide high quality manufacture and application solutions to customers in many fields directing the global economy such as automotive, marine, aviation technology, construction, heating and cooling, energy, petrochemistry, defense industries. Today, AKYAPAK machines are used in the factories of world s giants like Mitsubishi, Mercedes, Harley Davidson, Rolls Royce and Turkish aviation and defense industries, TAI and Roketsan. The construction processes of famous structures like Istanbul Ataturk Airport, Ataturk Olympic Stadium, Istanbul Park tribunes and of vehicles and constructions that are a part our daily life like automobiles, motorcycles, ships, airplanes, airports, bridges, stadiums, steel construction buildings, skyscrapers, wind turbines, petrol stations containes the signature of AKYAPAK machines. The primary reasons that make AKYAPAK a preferred one in Turkey and the world are precise quality control processes, inspection of every piece with due care and usage of materials of world-wide known brands. From the acceptance of parts to the assembly of products, the same high quality and customer oriented approach generate AKYAPAK production philosophy. CE, ISO 90012015, UKAS 005, TSEK, and TURQUM certificates officially prove AKYAPAK s quality and high standards.

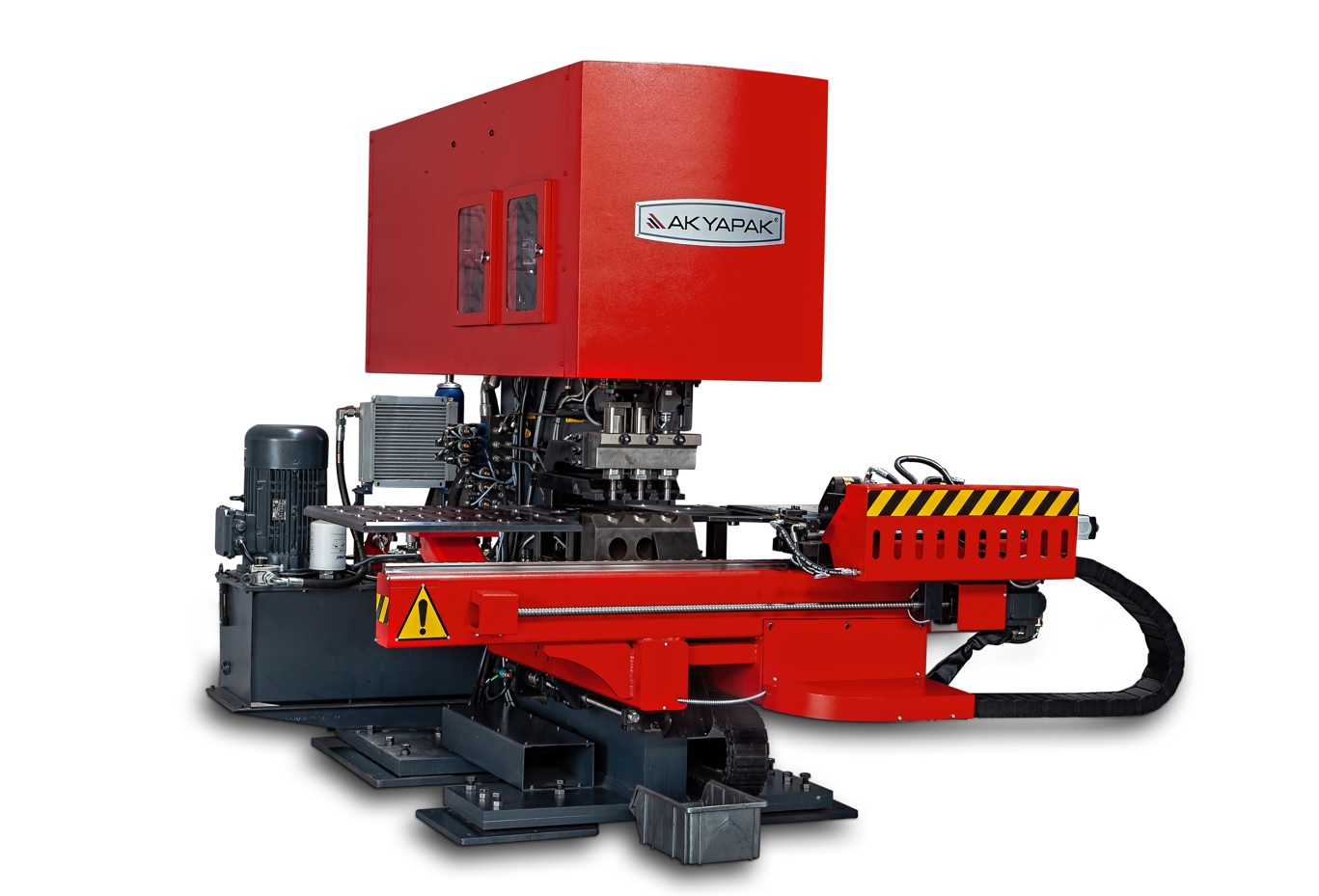

Akyapak, AKD Angle Punching, Shearing & Marking Line, provides a new production solution for power plant or electrical poles, towers, oil refineries and all steel construction works that require quick but high quality operations without wastage.

For APP 80 model, plate positioning with standard programming is limited to 1000×500 sized and 100kg weight part. Manually punching is possible for 1000×500 sized or 250 kg weight plate where the punching area is suitable.

AKYAPAK, as a leader of its sector, shows its technology in steel construction drilling lines and moves it from Turkey to the World. AKYAPAK, created AKDRILL brand in this sector, manufactures CNC drilling machine series with servo motor driven in the name of ADM for steel construction masts.

Advanced solution at steel construction sector once again from AKYAPAK High speed and high processing performance with AFD up to 1000×1500 mm materials.

The angled cutting position is adjusted by servo motor (brought to its position). It can be adjusted the cutting speed and its progress according to the material. Cutting speed=Band speed Cutting progress = The vertical movement of handsaw

4-Roll Plate Rolling Machines Great Solutions For Great Challenges Akyapak s 4-roll AHS model offers reliable and excellent solutions for precise and challenging rolling applications. It is the most reasonable choice to bend the materials with a plate thickness of 2 mm to 200 mm and with a plate width of 500 mm to 12000 mm. Prescide, Productive and Reliable As well as being reliable, AHS increases productivity with its high speed rolling ability and it overcomes the most challenging bends thanks to its ease of use. Since the plate is pinched during rolling, skidding and slipping of materials are prevented. Thus, more reliable rolling operations are performed and more precise results are achieved. In AHS 4-Roll Plate Rolling Machines, one of the side rolls can be used as a squaring roll, thus the plate can be easily and precisely aligned along the roll across the input direction.

Column Boom Systems While Column-Boom systems can perform welding independently for any part, it may also perform circular or lengthwise welding using rotator or positioner. Welding types that can be performed by the system are SUBMERGED, MIG, MAG, TIG. Also, Column-Boom systems can be fixed or with automatic travel on rail. Column-Boom systems enables improvement of quality, reduction of manufacturing time and operator fatigue, precision and continuous welding quantity that can be realized by an operator. Akyapak Makine includes 3×3 to 9×9 Column-Boom systems in its standard lists. However, custom production can be realized up to 10 x 10 meters..

Angel Rolls (Heavy Series) We Have Exceeded The Size Limit On Angle Rolls AKYAPAK offers extensive alternatives on heavy duty profile bending machines as well. Our machines are strong and reliable with their St-52 weld construction body. Minimum flexion causes less deformation, by the help of our machines enlarged roll diameters. By the help of big measurements of bearings, durability and high bending momentum can be obtained.

Tube Bending Machine You will get perfect bending results up to 38 mm tube diameters with AKYAPAK ABM 38 CNC Tube Bending Machines. This machine provides great convenience and increases efficiency with its advanced CNC feature.

No represented companies found.

The company has no registered brand information.

TR

TR