| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

DENER MAK. SAN VE TİC AŞ

Sultansazı OSB. 6. Sok. No:12 / İncesu / KAYSERİ / TÜRKİYE

|

Contact Info: +90 352 321 1350

|

Hall: 4

Stand: 407

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Dener Makina was established in 1974 in Kayseri Old Industrial Zone. Since 2000, Dener Makine has focused on the production of CNC Sheet Metal Processing Machines and continues its production with a wide range of products including Guillotine Shears, Hydraulic Press Brakes, Ball Screw Press Brakes, Servo Electric Press Brakes, Plasma Cutting Machines and Fiber Laser Cutting Machines. In 2016, the company made a significant investment by incorporating 155,000 m² factory buildings and 27,000 m² social facilities located on 1,300,000 m² of land owned by TAKSAN A.Ş. In the new period, Taksan Integrated Facilities started the production of CNC Metal Processing Machines such as Double Column Machining Centres, 5 Axis Simultaneous Machining Centres, Vertical Machining Centres, Lathes and Grinding Machines. Dener Makina, CNC Sheet Metal Processing Machines and CNC Metal Processing Machines, with its wide range of machinery production, half a century of experience, qualified workforce and multinational R&D centre, is the first in the world by offering important investment products to the world industrial enterprises.

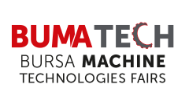

Dener PUMA XL CNC Press Brakes are born with the aim of being flexible, reliable, and advanced bending machines; During their production, our company uses the strictest manufacturing technologies to achieve the highest quality. Based on a proven design, Dener has increased the working speed, the capacity in the strokes and the daylights and the folding accuracy of the Puma XL machines. DENER PUMA XL is a synchronized hydraulic press brake with a 3D graphical CNC controller and offers easy machine operation and setup, simple and fast 3D of numerical parts programming, and auto calculation of the bend sequence. The 3D and DXF programming features with ESA S 660 W controller provides more possibilities to end users to increase their production. These functions make Dener PUMA XL CNC Hydraulic Press Brakes very popular in the metal forming industries.

No product info found.

Dener CNC Servo Electric Press Brakes are no-hydarulic, flexible, reliable and advance bending machines. A next generation machine idea that combines green-eco firendly machines productivity, accuracy, flexibility and reliability. The new concept offers low energy consuption, less maintenance, without hydarulic oil for operation. Dener Electric Press Brakes come with an advance CNC controller, fast and accurate puncher and die clamping and a multi axis back gauge system. Making sheet metal bendings at lowest possible cost is very easy.

Dener Ball Screw Press Brakes are no-hydarulic, flexible, reliable and advance bending machines. A next generation machine idea that combines green-eco firendly machines productivity, accuracy, flexibility and reliability. The new concept offers low energy consuption, less maintenance, without hydarulic oil for operation. Ball Screw Press Brake comes with advance CNC controller, fast and accurate punch and die clamping multi axis back gauge system. Operators can easily make metal parts at a very low cost.

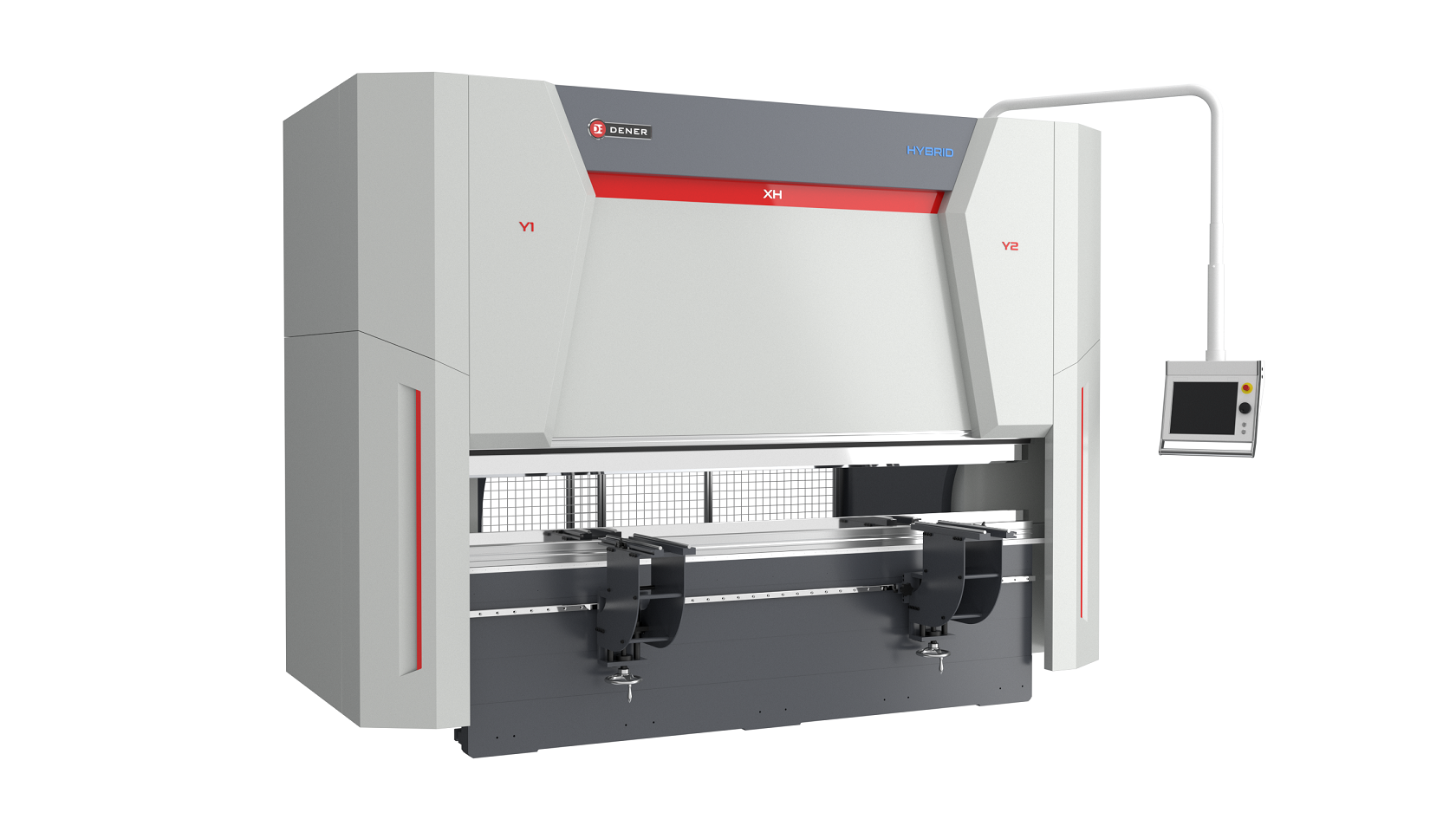

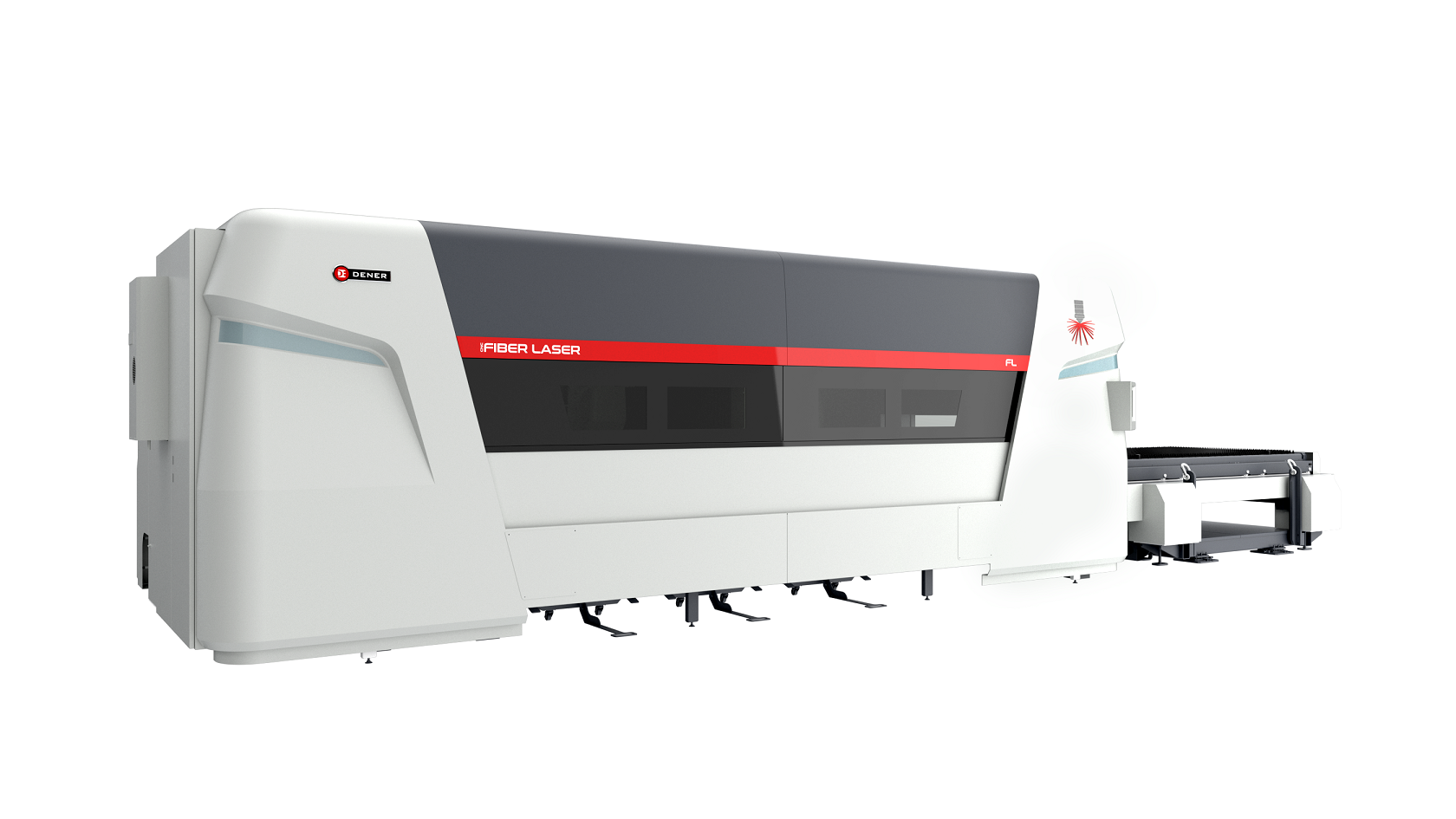

Dener Fiber Laser Cutting Machines with various power options are an unrivaled machine with low energy consumption, fast cutting capacity and minimum maintenance cost. Fiber laser is a laser cutting machine with high efficiency and high segment standards. Dust collection covers are opened or closed according to the movement of the cutting head. At the same time, it ensures that there is no burning odor in the operating environment and the smoke generated during the cutting process is discharged. The double cutting table system is designed to increase workflow, easy material placement and reduce the time spent on lifting materials. With the automatic sheet recognition feature, the angle and corner of the sheet relative to the machine are automatically calculated with the 3-point identification method on the sheet. Fiber lasers do not need maintenance. They are long-lasting, with a diode life of approximately 100,000 hours.

No product info found.

No represented companies found.

The company has no registered brand information.

TR

TR