| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

KURŞUNEL KALIP MAKİNA OTO YED.PARÇ.SAN.TİC.LTD.ŞTİ

FEVZİÇAKMAK MAH. 10644. SOK. NO: 61 / KARATAY / KONYA / TÜRKİYE

|

Contact Info: +90 332 345 0805

|

Hall: 6

Stand: 607/A

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

KURŞUNEL KALIP was founded by Hasan Kurşunel in 1985 and has become a trademark representing quality by keeping up with the developing technology. Kurşunel Kalıp has strengthened its technological infrastructure day by day and has become one of the pioneers in the production of sheet metal progressive moldings and welded construction painted sheet metal parts in its modern factory having a large workshop park and an indoor area of 4000 m2. We gained ground with steady and determined steps on this journey that we started in 1985 as Kurşunel Kalıp, and our experience of more than 30 years has created the trademark Kukamet. We have started to produce manual and pneumatic toggle clamp, pneumatic swing clamp and pneumatic gripper in 2010 and have reached a product range of more than 1000 models. Our company, that has become a leader in Turkey by making an effective access to market with the quality and pricing of by us, has also gained a competitive position in the world with other companies. By means of our increasing export and our leading position in the domestic market, our brand recognition and brand strength are constantly increasing. We are taking take the justified pride of being the first and only local firm which could take place in written specifications of leading firms in various sectors from automotive and defense industry to transportation systems and energy. We enrich the production in many industries such as automotive industry in particular, defense, aviation, rail transportation, white appliances and machinery. Kukamet also installs the first automated assembly line in Turkey and produces accurate products at a time faultlessly and in standard tolerances. Kukamet has made the products more qualified in the production of the clamps by using the metal that is produced specially. Our experienced production team performs production with the approach of zero-defect at every stage through automation and robotic system. It is ensured that the waste is zero in material handling and in operation periods of labor power. Each product is designed in the computer environment down to the finest detail with the CAD/CAM programs used by automotive giants. All the products are controlled by our quality control specialists and their cycle times are determined and strength tests are carried out in the laboratory. We believe that working systematically with a strong team is the greatest reason why our customers prefer us. We think that it is not enough to just exist, and believe that it is essential to increase in size by developing. Our systematic work is based on ISO 90012015 certification we have had since 2004. Kukamet takes fast and firm steps forward to become the best manual and pneumatic clamp manufacturer in the world. Kukamet is conducting more extensive researches to offer innovative products that supports the production and always offers the better for you.

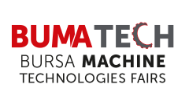

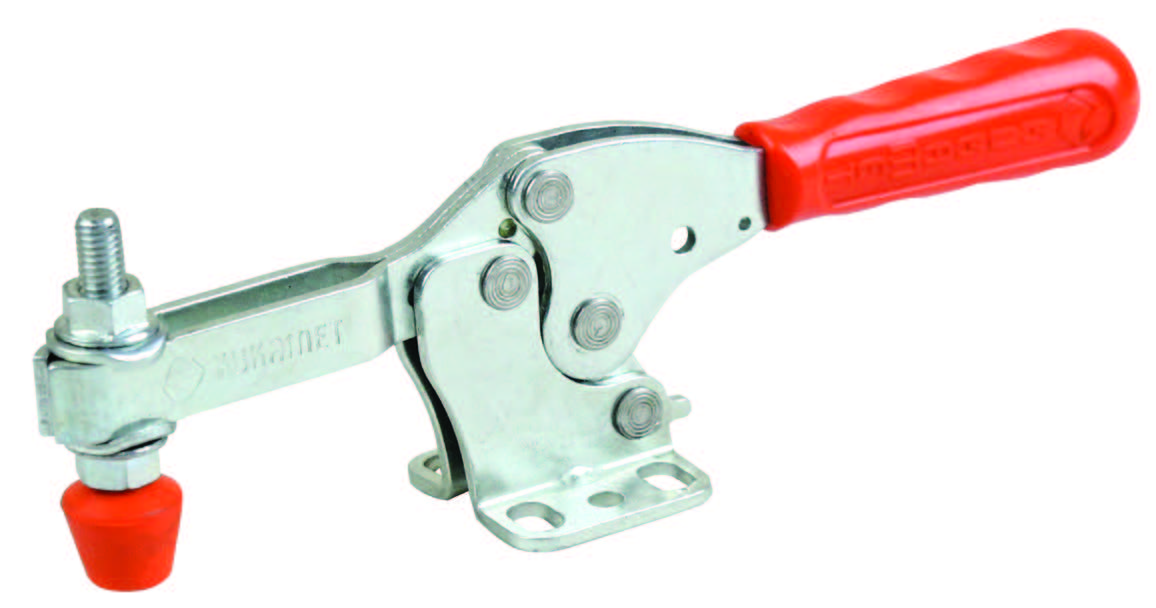

ST52 grade steel Stainless rivets 304 quality and heat treated bushings Not be harmful to health polyurethane handles are ergonomic, easy grabbing and resistant to oil and break

ST52 grade steel Stainless rivets 304 quality and heat treated bushings Not be harmful to health polyurethane handles are ergonomic, easy grabbing and resistant to oil and break

The modular series is thanks to the forged steel arms, hardened bushings and grinded pins capable of handling the heaviest jobs with long endurance without any problem

ST52 grade steel Stainless rivets 304 quality and heat treated bushings Not be harmful to health polyurethane handles are ergonomic, easy grabbing and resistant to oil and break

The products are strong and suited for heavy duty applications. The base, arm and stretching part are made of strong GGG-60 casting and coated with black electrostatic powder paint. Hook and pins are made of galvanized steel for corrosion resistance.

ST52 grade steel Stainless rivets 304 quality and heat treated bushings Not be harmful to health polyurethane handles are ergonomic, easy grabbing and resistant to oil and break

The products are strong and suited for heavy duty applications. The body is made of strong GGG-60 casting and coated with black electrostatic powder paint. The rod is made of hard chrome plated steel for high wear and corrosion resistance and the mechanism parts are made of galvanized steel for corrosion resistance.

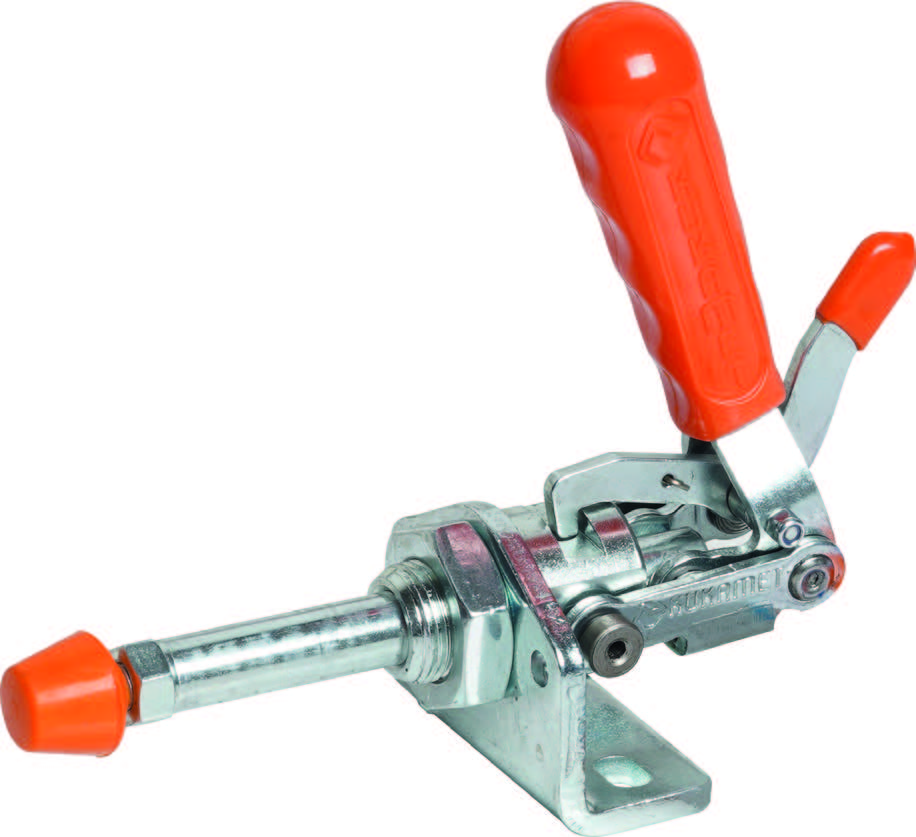

Pneumatic cylinders are double acting, magnetic and cushioning Assembly with different connection bases at various positions High-quality steel sheet parts are galvanized Stainless rivets (304 quality) and heat treated bushings

-Cylinder is double acting -The body is made of strength aluminum. Anodised for Corrosion resistance. -The piston rod is hard chrome plated and shapely polished for to high wear resistance and corrosion resistance.

- Standard heat resistant up to 80°C. heat resistant up to +200°C. If the wiper rod seal and o-rings are changed - 0-135° angle range - Gapless jaw pressure - Dust tightness test certificate (IP5) - Slag-free aluminum body (Hot shaped from 6082-T6) - Sensor - Ease of maintenance with quick and easy disassembly - Oval cylinder with hard anodized finishing - Shaft straightness due to bearing top cover - Removing the cap on the cover and adjusting the jaw angle with a single allen - Thanks to the machined surface, ease of connection from 4 directions - Special designed adjusting bolt

No represented companies found.

- KUKAMET

TR

TR